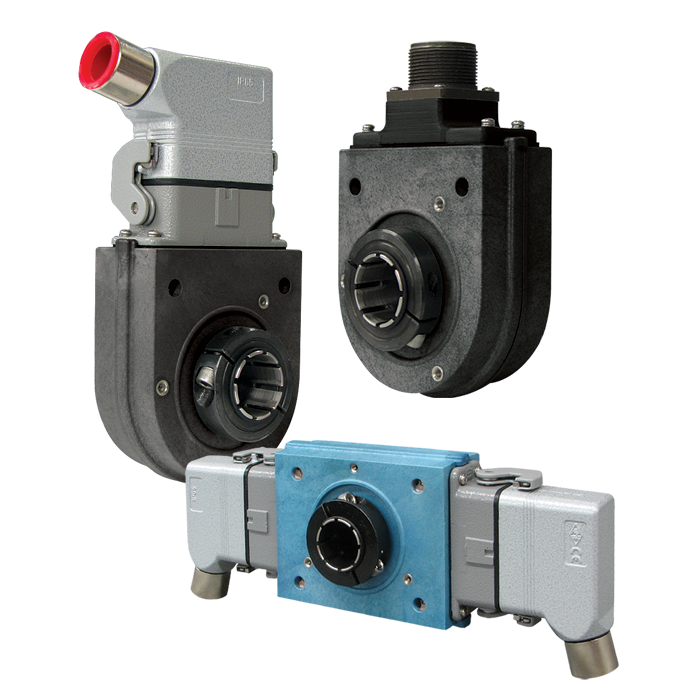

HOLLOW SHAFT ENCODERS

What is a Hollow Shaft Encoder?

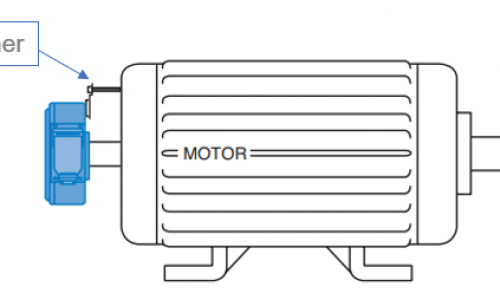

A hollow shaft (or hollow bore) encoder is designed to be mounted onto a shaft. The rotor of a hollow shaft encoder, where the shaft is mounted, can be manufactured to a wide range of sizes. One of the lead advantages of this design is that it eliminates the need for a coupling.

Encoders with a hollow shaft can be incremental or absolute depending on the need or application, and they can be mounted at the end of a shaft (end of shaft) or have of thru-shaft mount.

To maximize durability, hollow shaft encoders must be mounted on shafts that have limited runout/ eccentricity. Avtron recommends that shaft runout (TIR) does not exceed (0.004”) / [0.10mm]

How does a Hollow Shaft Encoder work?

As the shaft rotates, the rotor inside the encoder rotates with it. The encoder then transforms the mechanical motion into square wave signals that are communicated to a control (PC, HMI, PLC or VFD) to determine speed, position, distance, or sense of rotation.

Hollow Shaft Encoder Uses & Applications

Hollow shaft encoders are commonly used in applications where a solid shaft encoder is not practical, such as in large rotating machinery or when a shaft must pass through the encoder. They can be used in a variety of industries, including manufacturing, automotive, and robotics.

Looking for a custom solutions?

Do you need custom modifications for your application?

Use the Contact Us form below to tell us what you need.

Contact us