Dramatically slash encoder-related downtime on top drive applications!

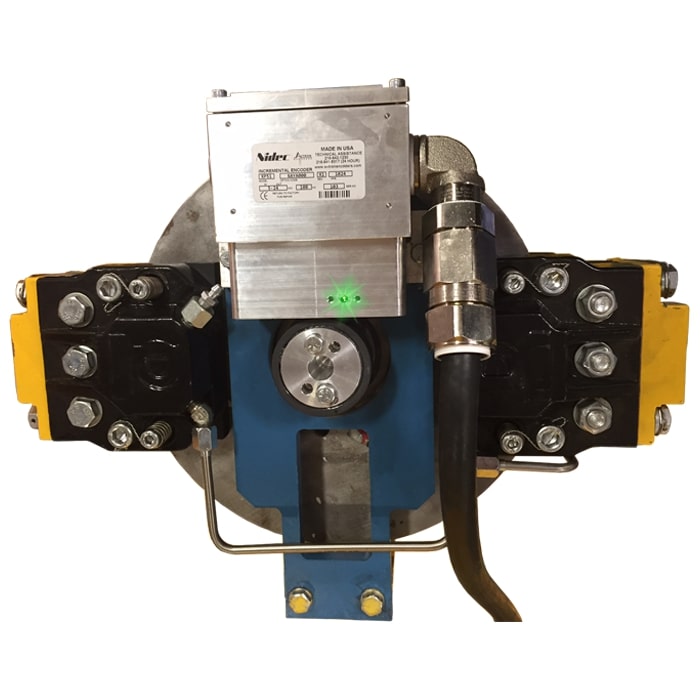

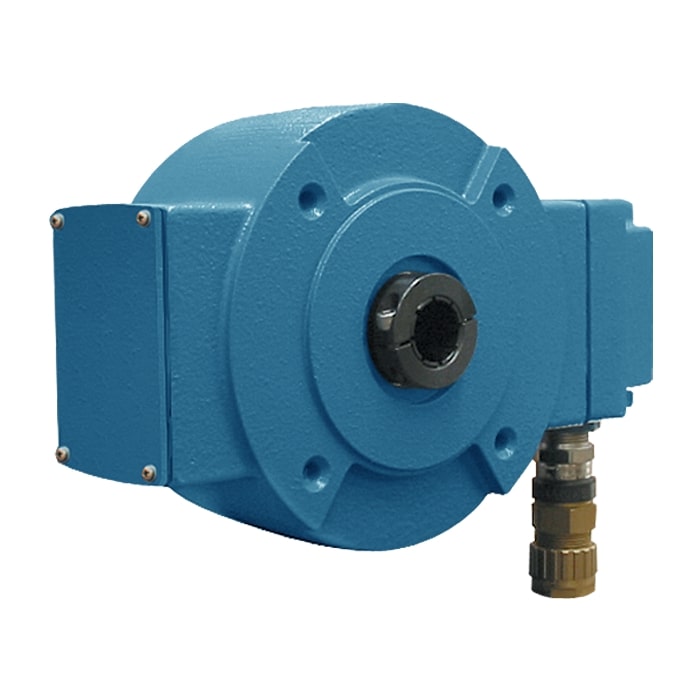

XPH1 SMARTSafe™ encoders are the world's first explosion-proof encoders with removable electronics and no external barrier! They are cULus, ATEX, IECEx certified and offer incredibly reliable no-bearing construction! SMARTSafe XPH1 encoders can be used in ATEX/IECEx, cUL AEX, and UL gas hazardous environments including NEC500 and NEC 505.

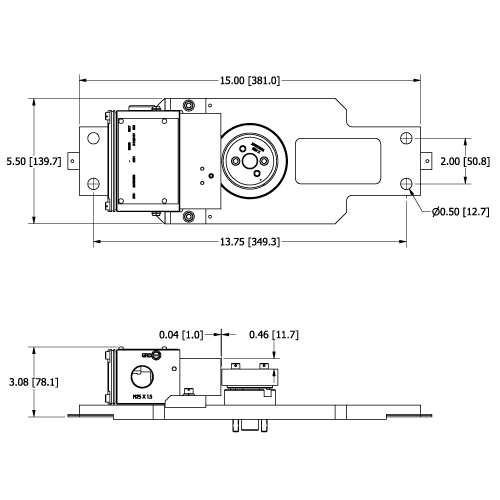

XPH1 comes complete with auto-centering jig, base plate, riser shaft, sensor and rotor to fit NOV TDS9, TDS10, and TDS11. Also available: no-bearing modular sensors (XP5), 8.5" C-face XPH8 as well as intrinsically safe models (XR5, XR12, XR56A, XR125, XR485, XR685, XR850) and hollow shaft models M6C.

Use the XPH1 directly in your application with no barrier or isolator required with 1000 feet of cable or more!

Unlike the competition, Avtron SMARTSafe encoder systems are protected against short circuits, power-to-output wiring, and output-to-ground faults. They feature full diagnostics: it's easy to determine that signal quality is good-just look for the green LED. Worried about wiring short circuits and errors? XPH1 will indicate any short circuit conditions with an orange LED and will survive this condition!

No encoder bearing failures, no more sealing problems. Mount XPH1 directly on your motor, build it right into your machine. So many applications benefit from a more reliable no-bearing encoder. Vibration, shock, liquids, dust and dirt won't harm SMARTSafe XPH1 encoders!

Eliminate the biggest cause of hazardous duty encoder failure--eliminate the bearings with XPH1 hazardous duty encoders!

Operating Power: 5-24VDC in/out

400mA max @ 5V; 200mA max @ 12V; 100mA max @ 24V (plus cable load)

Output Format: A Quad B with marker (A, /A, B, /B, Z, /Z)

Frequency Range: 0 to 250 kHz

PPR: 8-100000

Speed: 6000 RPM Max. (contact factory for higher speeds)

Maximum Cable Length: 1000 ft (305m) (contact factory for longer distances)

Rotor Positioning: Up to +/-0.100" [+/-2.54mm] movement/misalignment

Sensor-Rotor Gap: 0.040", +0.015/-0.030" [1mm+0.38/-0.76]

Temperature: -50°C to 85°C

(rotor -50°C to 100°C continuous, +135°C intermittent)

Environmental: IP65 fully potted sensors

Vibration: 5-2000Hz, 18G; 100G Shock

Weight: 15lbs. [6.8kg]

Certifications:

Class I Div 1, Groups C and D*

Class I Zone 1, Ex db ia IIB T4 Gb*

Class I Zone 1, AEx db ia IIB T4 Gb*

Ex db ia IIB T4 Gb (ATEX/IECEx)*

*See installation drawings for Warnings and Limitation

**Consult NOV for installation guidelines and details

- All-digital design, no trim pots or adjustments for longer life

- Advanced sensor technology

- Superior line drivers withstand short circuits and reverse voltage wiring errors

- Fully Potted Electronics

- SMARTSafe sensors find problems before they cause failure

- Allows Gland or Conduit Connections

- Full protection against motor shaft currents

| Industry | Mining | General | Wind Power | Pulp & Paper | Oil & Gas | Marine | Metals | Machinery | Crane & Hoist |

|---|---|---|---|---|---|---|---|---|---|

|

|

|||||||||

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

||||

|

|

-

PQAN ATEX Cert.

-

Nidec-Avtron Terms and Conditions

-

ATEX-EU Type Certificate US/UL//ExTR17.0051/02 for XP Models

-

ATEX EU-Type Cert. XP Zone 1

-

Class 1, Div 1 Class 1, Zone 1 Cert. XP Encoders

-

Nidec Industrial Solutions ISO Certificate

-

IECEx Quality Assessment Report (QAR 12.0002/10)

-

SMT1 Brochure

-

Avtron Encoders Product Catalog

-

IECEx Cert. XP IECEx UL 17.0049X

-

ATEX Declaration of Conformity for XP Models

-

REACH & RoHS

No Related Materials Available